High Speed Stacking Door

China’s Premier Manufacturer and Supplier of Industrial High-speed Stacking Doors

As a leading industrial door manufacturer in China, SEPPES offers robust and high-performance high-speed stacking door solutions specifically engineered for large openings and high-wind environments. Our doors are widely utilized in logistics centers, heavy industry plants, and large-scale warehouses where speed and wind resistance are critical.

Our dedicated engineering team provides both customized and standard products featuring reinforced wind-resistant bars and advanced automated control systems. Designed to operate reliably under the most demanding conditions, SEPPES stacking doors ensure maximum energy efficiency and operational safety. Discover the unmatched durability of our solutions and contact us today to receive expert technical support and exceptional service!

Home » High Speed Door » Stacking door

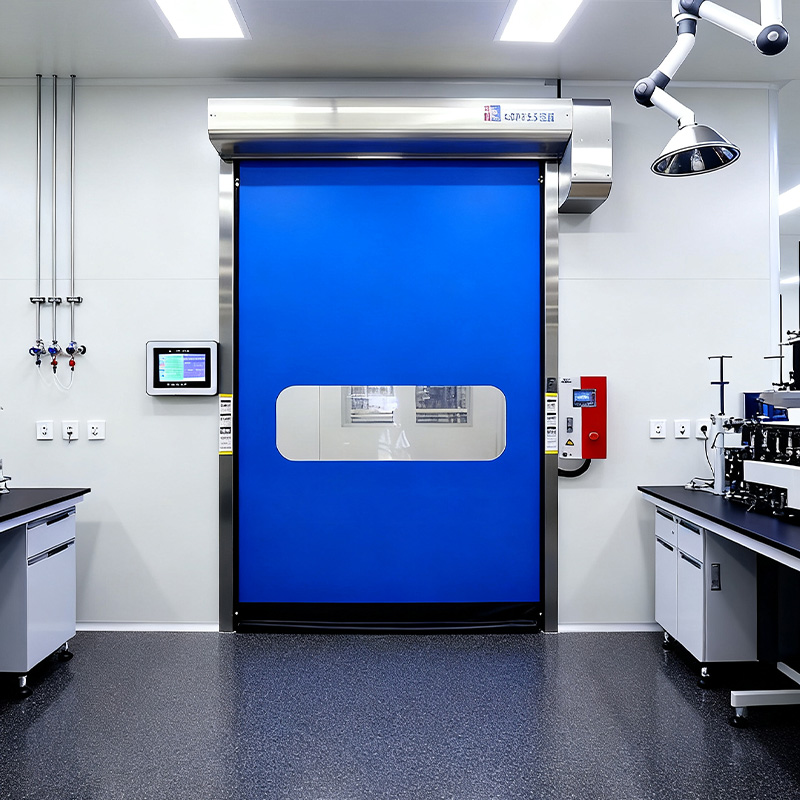

Durable, High-Wind Resistant Stacking Door for Large Openings

Superior Speed Performance & Robust Weather Protection

Superior Wind Resistance for External Openings Constructed with high-strength horizontal reinforcement ribs to withstand strong wind pressure and harsh weather conditions in large-scale facilities.

Rapid Operating Cycles for Enhanced Productivity The high-speed folding mechanism ensures quick passage, significantly reducing air exchange to maintain stable indoor environments and optimize workflow.

Heavy-Duty PVC Fabric for Long-Lasting Durability Made from high-tenacity polyester fiber with a double-sided coating, designed for wear resistance and reliable performance in demanding industrial areas.

Customizable Vision Strips and Sizes for Large Portals Tailored to fit extra-large warehouse entrances with optional transparent windows to improve natural lighting and operational safety.

Advanced Intelligent Safety Systems Equipped with infrared safety sensors and bottom pressure wireless sensors to ensure the highest level of protection for personnel and vehicles.

Key Features of High-speed Stacking Doors

Make Your Factory Look Cleaner and Your Entrance Gate Smarter.

Reinforced Wind Resistance

High-strength horizontal aluminum alloy ribs allow the door to withstand extreme wind loads on large external openings.

Superior Environmental Sealing

Integrated double-sided sealing brushes and a heavy-duty bottom seal effectively block dust, insects, and outside noise.

High-Speed Folding Action

The advanced vertical stacking mechanism ensures rapid opening and closing to maximize logistical efficiency and productivity.

Enhanced Operational Safety

Standard infrared safety sensors and wireless safety edges provide immediate protection for personnel and vehicles during operation.

High-Speed Stacking Doors (Heavy-Duty)

- Extreme Wind Resistance: Engineered with horizontal steel or aluminum reinforcement ribs to withstand high-pressure exterior environments.

- Large-Scale Versatility: The specialized folding mechanism allows for much larger spans, making them the premier choice for massive industrial bay openings.

- Heavy-Duty Stacking System: Uses high-tenacity lifting straps to fold the curtain upwards, ensuring structural stability during high-intensity operation.

- Rugged Exterior Performance: Specifically built for long-term durability in harsh weather, coastal areas, or exposed loading docks.

Standard PVC Brush Doors (Indoor Efficiency)

- Precision Brush Sealing: Equipped with dense brush tracks to minimize air exchange and block dust, pests, or contaminants in internal areas.

- Lightning-Fast Operation: The lightweight roll-up curtain allows for ultra-high-speed cycles, optimizing high-frequency indoor logistics throughput.

- Compact Space-Saving Design: The curtain rolls neatly onto a top drum, requiring minimal header space for installation in tight workshop corridors.

- Cleanroom Compatibility: Ideal for pharmaceutical, food processing, or internal partitions where hygiene and environmental control are paramount.

Staking Door Detailed Technical Specifications

| Product Name | Standard Stacking Door | Heavy-Duty Stacking Door | High-Wind Load Stacking Door | Large-Scale Stacking Door |

|---|---|---|---|---|

| Product Features | Wind Resistance: Excellent Opening Speed: High Durability: Good Seal: Weatherproof | Wind Resistance: Superior Opening Speed: Moderate Durability: Excellent Seal: Enhanced | Wind Resistance: Ultra-High Opening Speed: High Durability: Heavy Duty Structure: Reinforced | Wind Resistance: High Opening Speed: Stable Durability: Excellent Custom: Oversized |

| Max Size | W6000 * H6000mm | W8000 * H8000mm | W10000 * H10000mm | W15000 * H12000mm |

| Frame Material | 2.0mm Powder Coated Steel / Stainless Steel | 2.5mm Powder Coated Steel / Aluminum Alloy | 3.0mm Galvanized Steel with Reinforced Paint | 4.0mm Heavy Duty C-Channel Steel |

| Curtain Material | 0.9mm / 1.2mm PVC Fabric | 1.2mm / 1.5mm PVC Fabric | 1.5mm Reinforced PVC | 1.5mm Double-layer Reinforced PVC |

| Curtain Color | Yellow / Orange / Blue / Grey / White / Full Clear | (Same as Standard) | (Same as Standard) | Yellow / Grey / Blue |

| Wind Resistance Bar | Φ22mm-Φ32mm Aluminum Alloy Tubes | Φ40mm-Φ50mm Steel/Aluminum Tubes | Reinforced High-Tensile Steel Tubes | External Heavy Lattice Truss Bars |

| Wind Load Class | Class 8-9 (≤ 800Pa) | Class 9-10 (≤ 1000Pa) | Class 11-12 (≤ 1200Pa) | Class 10 (Customized) |

| Motor Power | 0.75Kw / 1.5Kw (Servo) | 1.5Kw / 2.2Kw (Servo) | 2.2Kw / 3.7Kw (Brake Motor) | 3.7Kw / 5.5Kw (Dual Motor System) |

| Opening Speed | 0.6 - 1.2m/s | 0.6 - 1.0m/s | 0.5 - 1.0m/s | 0.3 - 0.8m/s |

| Closing Speed | 0.6m/s | 0.6m/s | 0.5m/s | 0.3m/s |

| Lifting Method | High-strength Polyester Lifting Straps | Multi-strand Braided Belts | Reinforced Steel Cables / Belts | Heavy Duty Steel Wire Ropes |

| Safety Devices | Photocell Sensor + Safety Bottom Edge | (Same as Standard) + Light Curtain | (Same as Standard) + Radar | Multi-point Photocell + Anti-fall Brake |

| Vision Window | Standard: Row 3/4 Horizontal Window | Optional: Multiple Rows / Rectangular | Optional: Small Square Windows | N/A (Optional) |

| Sealing Structure | Double Row Industrial Brush | Heavy Duty Brush + Bottom EPDM Seal | Wind-proof Track Brush + Large Bottom Seal | Triple-layer Weather Stripping |

| Frequency | 600 - 800 cycles/day | 500 - 700 cycles/day | 400 - 600 cycles/day | 200 - 400 cycles/day |

| Working Temp. | -25℃ ~ +70℃ | -25℃ ~ +70℃ | -30℃ ~ +70℃ | -30℃ ~ +70℃ |

| Track Dimensions | W120mm * L100mm | W150mm * L120mm | W180mm * L150mm | W250mm * L200mm |

Key Features to Consider When Choosing a Staking door

Superior Wind Resistance for Large Exterior Openings

Engineered for resilience, high-speed stacking doors are the preferred solution for large-scale industrial entrances exposed to heavy wind loads. Featuring integrated horizontal reinforcement ribs, these doors provide exceptional structural stability that standard rolling doors cannot match. They are specifically designed for expansive openings in shipyards, hangars, and logistics hubs where they must withstand strong gusts while maintaining rapid operation. This robust design ensures your facility remains secure and functional even in the most demanding weather conditions, preventing downtime caused by wind damage.

Safety and Protection Systems

- Infrared Safety Photocells monitor the doorway in real-time, triggering an automatic reverse if any person or vehicle is detected to prevent collisions.

- Flexible Safety Bottom Edges provide instant contact protection, halting downward motion immediately upon the slightest touch to safeguard personnel and equipment.

- Emergency Manual Overrides ensure reliable operation during power failures, maintaining safe access and clear evacuation routes for high-traffic industrial zones.

Optimizing High-Traffic Logistics and Efficiency

For facilities prioritizing operational speed, these doors offer a high-performance folding design that handles intensive traffic with ease. In fast-paced environments where forklifts and transport vehicles are constantly on the move, every second counts. High-speed stacking doors utilize a powerful drive system to provide lightning-fast opening and closing cycles, significantly reducing wait times and streamlining the flow of goods. This makes them an essential investment for busy distribution centers and manufacturing plants looking to maximize throughput and minimize the risk of collisions in high-traffic zones.

Choose The Optimal High-speed Stacking Door For Your Facility

SEPPES provides robust, wind-resistant stacking solutions to maximize your operational efficiency and large-scale entrance security.

Reinforced with high-strength horizontal ribs

Engineered for large-scale exterior openings

Exceptional stability against heavy wind loads

Powered by advanced industrial drive systems

Designed for 24/7 high-intensity traffic flow

Optimizes logistics efficiency and reduces energy loss

Multi-point infrared sensors for real-time monitoring

Intelligent controller with customizable operation modes

Maximum protection for personnel and cargo

Diverse High-Speed Door Solutions For Industrial Efficiency

Standard PVC High-Speed Door

Designed for internal areas requiring rapid opening and closing cycles. These doors improve airflow control, minimize dust contamination, and are highly cost-effective for manufacturing plants and cleanroom environments.

Self-Repairing Zipper Door

Features a specialized zipper track that allows the curtain to automatically re-insert itself if dislodged by an impact. Its superior sealing makes it ideal for food processing and pharmaceutical sectors where hygiene is paramount.

Insulated High-Speed Door

Constructed with double-layered PVC filled with thermal insulation material. These doors prevent energy loss between temperature-controlled zones and ambient areas, significantly reducing HVAC costs in cold storage logistics.

Hard Aluminum High-Speed Door

Combines the speed of a fabric door with the security of a sectional door. Utilizing a non-contact spiral track, it provides rapid operation for exterior entrances while offering robust protection against unauthorized entry.

Common Applications For High-speed Stacking Doors

Why Choose Our High-Speed Stacking Doors?

Superior Wind Resistance: Built with high-strength reinforcement ribs to withstand extreme pressure in large exterior openings.

High-Speed Efficiency: Rapid opening cycles streamline logistics flow and minimize energy loss during intensive 24/7 use.

Large-Scale Customization: Tailored for oversized industrial spans while maintaining perfect structural integrity and stability.

Advanced Safety Systems: Integrated infrared sensors and smart controls provide real-time protection for personnel and cargo.

Industrial-Grade Durability: Heavy-duty materials and simplified folding mechanics ensure long-term reliability and low maintenance.

High-Speed Stacking Door Expertise And Project Experience

- Wind-Resistant Stacking Doors for Large Exterior Openings

- Heavy-Duty Stacking Doors with Horizontal Steel Ribs

- High-Strength Folding Doors for Coastal & Storm-Prone Areas

- External High-Speed Doors for Extreme Weather Resilience

- Reinforced Stacking Doors for High-Pressure Environments

- Impact-Resistant Folding Doors for Demanding Industrial Sites

- Galvanized Steel Frame Doors for Long-Term Durability

- Vertical-Folding Stacking Doors for Maximizing Header Space

- Rapid-Action Stacking Doors for High-Traffic Logistics Hubs

- Space-Saving Folding Doors for Oversized Machinery Access

- Automated Stacking Doors for Smart Distribution Centers

- High-Frequency Folding Doors for 24/7 Logistics Operations

- Intelligent Control Doors for Seamless Forklift Passage

- Low-Maintenance Stacking Doors for Operational Excellence

- Energy-Efficient Folding Doors for Sustainable Warehousing

- Smooth-Operation Stacking Doors for Reduced Mechanical Wear

- Airtight Stacking Doors for Waste & Recycling Facilities

- Dust-Proof High-Speed Doors for Agricultural Storage

- Safety-Integrated Stacking Doors for Heavy Manufacturing

- Bespoke Large-Scale Doors for Aircraft Hangars & Shipyards

- Weather-Sealed Stacking Doors for Cold Storage Loading Bays

- Sound-Insulating Stacking Doors for Noisy Production Zones

- High-Visibility Stacking Doors with Integrated Vision Panels

- Anti-Corrosive Stacking Doors for Chemical & Fertilizer Plants

What Our Client Says

Build your project with confidence knowing that customers across industries trust SEPPES

Expert Guides To Custom Industrial Stacking Doors

Q1: What is the primary difference between a stacking door and a standard rapid roll-up door?

A: The primary difference lies in wind resistance and size capability. Stacking doors use horizontal reinforcement ribs and a folding mechanism to withstand much higher wind pressures, making them ideal for large exterior openings where standard roll-up doors might fail.

Q2: How does the door achieve such high wind resistance?

A: These doors are engineered with integrated high-strength steel or aluminum reinforcement ribs. When the door closes, these ribs provide structural integrity against heavy gusts, and when opening, the curtain folds and “stacks” at the top.

Q3: What safety features are included to protect personnel and vehicles?

A: Our doors are equipped with multi-point infrared safety sensors to monitor the transit zone and flexible safety bottom edges that trigger an immediate reverse upon contact. These systems ensure maximum protection in high-traffic industrial environments.

Q4: Can these doors be customized for oversized industrial entrances?

A: Yes, stacking doors are specifically designed for large-scale customization. They are the preferred solution for massive spans in shipyards, aircraft hangars, and heavy manufacturing plants where structural stability is critical.

Q5: What is the typical operational speed of a stacking door?

A: Powered by advanced industrial drive systems, these doors offer rapid opening and closing cycles. This speed is essential for maintaining logistics efficiency and minimizing the time a building is exposed to outside elements.

Q6: Are stacking doors suitable for environmental control, such as dust or odor containment?

A: Absolutely. Their rapid action and tight perimeter sealing minimize air exchange, making them highly effective for waste management facilities, agricultural storage, and temperature-controlled warehouses.

Q7: What happens in the event of a power failure?

A: Every door includes an integrated emergency manual release mechanism. This allows operators to manually open or close the door during power outages, ensuring that vital logistics or evacuation routes remain unobstructed.

Q8: How durable are the materials used in SEPPES stacking doors?

A: We use high-density PVC curtains and heavy-duty galvanized steel tracks designed for 24/7 high-intensity use. The folding mechanism is engineered to reduce mechanical wear, ensuring long-term reliability and lower maintenance costs.

Related services provided by SEPPES Door

No posts found!

Latest Blog Posts about Industrial Sectional Doors

Learn more about industrial sectional doors , purposes of applications and all the most current developments. Don’t miss out on reading our professional blog redirection and come learn more!

Posts not found

Getting a quote for stainless steel cnc machining services

Would you like to invest in superior stainless products made precisely to last? If yes, kindly contact us to discuss the specifics of the project or ask for a custom quotation.

Frequently Asked Questions

Q1. Why choose us?

A: The most cost-effective products, high quality; professional technical sales support for pre-sales and after-sales service; over 15 years of manufacturing and customization experience.

Q2. What is your delivery time?

Answer: Loading port: Shanghai or according to your requirements. Generally, it takes about 15-20 days after sample confirmation.

Q3. What payment methods do you accept?

A: We typically accept payment via bank transfer in advance. If you prefer other payment terms, please feel free to contact us.

Q4. How can I get your prices?

A: Please give the exactly size and quantity of your required door. We can give you a detail quotation based on your requirements.

Q5. What is your MOQ?

A: 1 order for roll up door is OK.

We also suggest standard package for protection during shipment and promise 24h after-sales service.