High Speed Cold Storage Door

Top Cold Storage High Speed Door Manufacturers and Suppliers in China

SEPPES Cold Storage High Speed Doors are premium industrial rapid doors engineered for cold chain environments, temperature-controlled warehouses, freezers, and high-frequency logistics areas. These doors combine advanced insulation, fast operation, and robust sealing performance to ensure optimal temperature stability and operational efficiency worldwide. In the demanding world of cold chain logistics, maintaining temperature integrity while ensuring high-volume traffic flow is critical. SEPPES Cold Storage High Speed Doors are specifically engineered to solve the energy-loss pain point of refrigerated warehouses and food processing plants.

Home » High Speed Door » Cold Storage Door

Durable and Reliable Cold Storage Rapid Door for Your Factory Needs

- Thermal Resilience: Our freezer high-speed doors are built to handle extreme temperature differences.

- The bottom of our cold storage doors features an anti-frost heating system. Prevents ice accumulation and condensation in sub-zero temperatures.

- Engineered for high-cycle performance, capable of 2,000+ daily cycles.

- Customizable Sizes & Configurations to Suit Your Unique Needs

- Enhanced Safety for Peace of Mind

Key Features of Our Rapid Cold Storage Doors

Durable and efficient high speed cold storage doors with customized options, providing reliable energy solutions tailored to your needs.

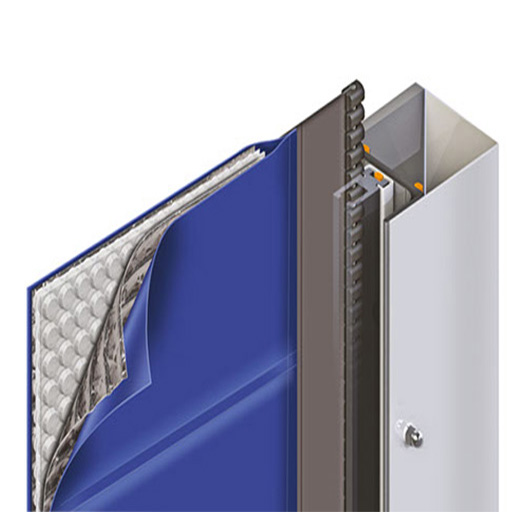

Multi-Layer Insulated Curtain

Unlike standard doors, the cold storage version features a thermal-insulated curtain (typically 12mm thick). It consists of double-layered PVC with an internal insulation material, providing a high R-value to block heat transfer effectively.

High-Performance System

Equipped with an advanced industrial servo motor, these doors achieve opening speeds to 0.8-1.8m/s. The high-frequency operation capability (up to 2,000+ cycles per day) is essential for busy logistics hubs, where the door must open and close instantly to minimize air exchange.

Anti-Freeze Heating System

To ensure 24/7 reliability, the bottom edge is integrated with an anti-frost heating system. This system prevents condensation and ice buildup in the tracks, ensuring the curtain never freezes or jams, even in high-humidity conditions.

Full Perimeter Sealing System

Equipped with a multi-layered sealing system around the entire door frame, including sealing brushes, rubber gaskets, and guide rail seals, this cold storage high-speed door effectively prevents cold air leakage and moisture ingress, significantly reducing the risk of frost buildup and condensation.

Traditional Exterior Sliding Doors

- Traditional Sliding Doors are notoriously slow, typically operating at a sluggish speed of 0.2m/s. This forces forklift drivers to stop and wait for a long time, creating significant logistical bottlenecks.

- The Traditional Sliding Door relies on thick, heavy panels that offer good insulation only when closed. However, they open and close so slowly, they allow a massive volume of warm, causing temperature spikes.

- One of the biggest pain points with Traditional Doors is their rigidity. If a forklift accidentally strikes the door panel, it results in structural damage, leading to expensive repairs.

- Without integrated heating, ice quickly forms on the tracks and seals, causing the motor to strain and the door to freeze shut, which poses a major safety risk to personnel.

Modern High Speed Cold Storage Door

- Our Cold Storage High Speed Doors revolutionize factory flow with speeds up to 1.8m/s. This efficiency boost directly translates into more shipments processed per shift.

- By combining multi-layer thermal curtains with ultra-fast cycles, they minimize the duration of air exchange. This keeps your internal temperatures stable and reduces the workload on your refrigeration compressors.

- Our Cold Storage Rapid Doors feature a Self-Repairing Zipper Structure. Designed without rigid metal components, the curtain detaches from the tracks upon impact and automatically resets itself on the next upward cycle.

- Advanced High Speed Doors are equipped with an Intelligent Anti-Frost Heating System. Low-voltage heating cables are embedded directly into the side guides and motor covers.

High Speed Freezer Door Detailed Technical Specifications

| Category | Parameter | Technical Specifications |

|---|---|---|

| Door Dimensions | Maximum Width | Up to 5000mm |

| Maximum Height | Up to 5000mm | |

| Customizable Sizes | Fully tailored dimensions based on site requirements | |

| Material Specs | Curtain Material | Triple-layer structure: 0.8mm PVC + double-layer tin foil insulation (Total thickness ~12mm) |

| Frame Material | SUS304 Stainless Steel (1.8mm thick) or Painted Cold-rolled Steel | |

| Insulation Properties | High-density thermal insulation with anti-frost heating system in tracks | |

| Operating Speed | Opening Speed | 0.4 - 0.8 m/s (Adjustable) |

| Closing Speed | 0.3 - 0.5 m/s (Adjustable) | |

| Control & Drive | Drive System | FROG PUPIL (German tech) industrial servo motor |

| Power Requirements | 220V, 0.75kW - 1.5kW, 50Hz (Standard) | |

| Limit Device | Multi-turn absolute encoder for high-precision limit memory | |

| Safety Features | Safety Sensors | Standard Infrared photocells on both sides of the frame |

| Anti-Crash System | Self-repairing zipper structure to prevent damage upon impact | |

| Emergency Stop | Manual push button for immediate halt during emergencies | |

| Durability | Wind Resistance | Class 4 rating with fiberglass interior wind ribs |

| Protection Grade | IP54 rated control box and motor protection | |

| Sealing Grade | Class 4 airtightness with double-layer PVC and bottom airtight seal |

Key Features to Consider When Choosing High Speed Cold Storage Door

Efficiency and Energy Savings

Equipped with high-speed drive systems, high speed freezer doors are essential for improving productivity and cutting expenses. This minimizes cold air loss and limits heat exchange between different temperature zones, helping to reduce the workload of refrigeration systems.

Mintain Stable Cold Chain Temperatures

- The door body adopts a multi-layer composite insulation structure filled with insulation materials inside, which can reduce heat conduction from the outside to the inside of the cold storage.

- The cold storage high-speed door is equipped with multiple sealing structures, such as sealing brushes, rubber sealing strips and sealed guide rails, which effectively prevent cold air leakage and moisture ingress.

- Motors, control systems and door curtain materials are all designed and tested for low-temperature working conditions, ensuring smooth operation in both refrigerated (0℃) and frozen (-10℃) environments.

Designed for Global Cold Storage Applications

As cold storage facilities continue to evolve toward energy-efficient, automated, and smart logistics systems, insulated high speed doors have become a standard solution.

Widely used in export-oriented warehouses and temperature-controlled distribution centers, these doors are engineered to meet international performance, safety, and durability standards, supporting long-term global operations.

Discover the Best High Speed Freezer Doors for Your Industrial or Business Needs

Find reliable cold storage door solutions for your factory or logistics. SEPPES High Speed Insulated Doors boost efficiency, ensure environmental control, and cut energy costs, offering durable, high-performance solutions for industrial needs.

Multi-layer insulated door curtain reduces heat transfer

High-speed opening and closing minimizes cold air loss

Full perimeter sealing improves thermal performance

Durable aluminum or stainless steel frame structure

Suitable for refrigerated rooms and medium-temperature cold storage

Anti-freezing heating system for tracks and sealing areas

High-performance sealing to prevent frost and condensation

Fast operation to reduce temperature fluctuation

Stable operation in freezer rooms down to deep-freeze conditions

Insulated door system designed for low-temperature environments

Material: PVC-coated fabric

Durability: Made with high-strength PVC fabric and wind-resistant pole

Supports maximum openings up to 5000mm in both width and height.

Features a Grade 4 wind resistance rating with built-in fiberglass wind ribs.

Uses an absolute encoder for high-precision limit setting, ensuring long-term operational stability.

Applications: Cold storage, food & beverage logistics, pharmaceutical, and where airtight sealing are critical.

Comparison of Common High Speed Roll Up Freezer Doors

SEPPES high speed roll up freezer doors boost efficiency, ensure environmental control, and cut energy costs. They offer durable, high-performance solutions for warehouse or factory needs.

| Feature | High Speed Insulated Door | High Speed Freezer Door | Stacking Freezer Door (Heavy Duty) |

|---|---|---|---|

| Model | SE-BWKSM-150 | SE-LKKSM-L350 | SE-LKKSM-L350 (Stacking) |

| Ideal Application | Ambient temp warehouses & buffer zones | Deep-freeze environments (down to -28°C) | Large-scale cold storage & high wind-load areas |

| Curtain Structure | Triple-layer: 0.8mm PVC + Aluminum Foil Air Cushion | Triple-layer PVC + Double-layer Tin Foil insulation | Triple-layer PVC + Double-layer Tin Foil insulation |

| Total Thickness | Approx. 3.0 mm | Approx. 12.0 mm | Approx. 12.0 mm |

| Opening Speed | 0.6 - 1.8 m/s (Adjustable) | 0.4 - 0.8 m/s (Adjustable) | 0.4 - 0.8 m/s (Adjustable) |

| Sealing Performance | U-shaped PVC track friction seal | Double-layer PVC airtight seal (Class 4) | Double-layer PVC + Airtight bottom seal (Class 4) |

| Anti-Frost Tech | N/A | Integrated track heating & optional de-icing | Integrated track heating & dual-protection design |

| Frame Material | 2.0mm Powder-coated Cold-rolled Steel | 1.8mm Thick SUS304 Stainless Steel | 1.8mm Thick SUS304 Stainless Steel |

| Max Dimensions | Standard Warehouse Sizes | Up to 5000mm (W) x 5000mm (H) | Up to 5000mm (W) x 5000mm (H) |

| Core Advantage | High-frequency use & cost-efficiency | Airtight insulation & self-repairing zipper | Extreme wind resistance & large-scale durability |

Technical Breakdown: Key Components of High-Speed Cold Storage Door

Airbag Bottom Edge

A high-sensitivity pressure sensor located at the bottom of the curtain. Upon contact with any obstacle or person during closure, the airbag system immediately triggers the door to stop and reverse to the open position.

Automatic Reset Structure

Often referred to as a Self-Repairing Zipper Design, this allows the curtain to detach from the track upon impact. If hit by a forklift, the door unzips without damaging the frame. On the next cycle, the curtain automatically re-inserts itself into.

Track heating system

Built-in low-voltage electric heating cables installed within the side tracks and motor housing. It prevents condensation and frost from forming in sub-zero environments, ensuring the moving parts don't freeze shut.

Multi-layer door curtain

A sandwich-structured door panel made of high-tenacity PVC and internal insulation foam. This multi-layer composite creates a superior thermal barrier, effectively blocking heat exchange and preventing energy loss.

What Types of High Speed Industrial Doors May You Like

High Speed PVC Door

High Speed PVC Doors are designed for indoor industrial environments with high traffic flow. Featuring flexible PVC curtains and fast operation, they improve workflow efficiency while controlling dust and temperature differences between areas.

High Speed Stacking Door

High Speed Stacking Doors are ideal for large industrial openings. The reinforced stacking curtain structure offers excellent wind resistance and durability, making them suitable for warehouses, logistics centers, and exterior doorways.

Zipper High Speed Door

Zipper High Speed Doors use a zip-guided structure to ensure the curtain stays securely within the tracks. This design provides superior sealing, self-repair capability, and enhanced safety, making it an excellent choice for clean rooms, food processing.

High Speed Spiral Door

High Speed Spiral Doors feature rigid aluminum panels and a spiral track system, combining high-speed operation with strong security and insulation. They are commonly used for factory entrances, logistics hubs, and exterior applications

Common Applications for High Speed Cold Storage Doors

Why Choose Our China SEPPES High Speed Cold Storage Door Products?

1. Cost Savings

High-speed cold storage doors from China SEPPES brand are 30-50% more affordable than U.S. or European options, offering significant savings even with shipping and tariffs.

2. Fast Production

China SEPPES brand ensures efficient delivery within 30-45 days for large orders, minimizing project delays and downtime.

3. Customization Options

China SEPPES brand provides tailored solutions, including size, material, and functionality adjustments, to meet diverse project needs.

4. Quality and Innovation

Door dock shelters meet ISO and CE standards, with advanced features like energy efficiency, anti-frost systems, and self-repairing designs.

5. Reliable After-Sales Support

China SEPPES brand offers warranties, remote troubleshooting, and quick part replacements, ensuring long-term reliability.

SEPPES Proven Expertise and Project Experience Across Diverse Industries

- cold storage high speed door for freezer warehouse

- insulated high speed door for cold storage rooms

- high speed freezer door for food processing plants

- cold chain warehouse high speed door solution

- energy saving high speed door for cold storage

- rapid roll up door for refrigerated warehouses

- high speed insulated door for pharmaceutical cold rooms

- cold storage rapid door for temperature controlled logistics

- industrial high speed door for cold chain facilities

- high speed door for cold room forklift access

- freezer warehouse rapid door for heavy traffic

- high speed freezer door for -18 degree cold storage

- high speed cold storage door for export warehouses

- insulated rapid door for frozen food storage

- freezer fast door for high frequency cold storage access

- cold storage rapid door with energy efficient design

- high speed cold room door for pharmaceutical storage

- insulated high speed door for seafood cold storage

- cold storage door for freezer warehouses

- high speed insulated door for vaccine cold chain

- industrial cold storage high speed door manufacturer

- cold storage high speed door for loading areas

- freezer rapid door with anti freezing system

- cold storage high speed door for food cold chain logistics

What Our Client Says

Build your project with confidence knowing that customers across industries trust baetro

Expert Guides to Custom High Speed Cold Storage Doors

How do I correctly measure the opening for a high speed insulated door?

Accuracy is critical for ensuring a proper thermal seal. Measure the clear width and height of the opening at three different points (top, middle, and bottom). Use the largest measurement for the opening size and ensure you have sufficient installation clearance.

Can I customize the size and material for my specific factory needs?

Yes. SEPPES cold storage doors can be customized for large openings up to 5000mm x 5000mm. For frame materials, you can choose between 2.0mm powder-coated cold-rolled steel or SUS304 stainless steel, which is ideal for food and pharmaceutical environments requiring high hygiene standards.

What are the voltage requirements? Can it work in my country?

Standard power requirements are 220V, 0.75kW to 1.5kW, 50Hz. While this is standard for many global regions (like Europe and China), we can often accommodate different power standards through specialized industrial transformers to ensure compatibility with your local grid.

Which opening method is best for my factory?

It depends on your traffic type:

For Forklifts/Vehicles: Geomagnetic induction or Radar sensing are most efficient for touchless, high-speed entry.

For High-Traffic Personnel: Remote control or Pull-rope switches provide more controlled access.

For Smart Warehouses: We support integration with AGVs, face recognition, or fingerprint systems.

How does the door perform in extreme freezer temperatures?

For deep-freeze environments down to -10°C, our doors utilize a triple-layer thermal curtain (PVC + insulation foil) with a total thickness of approximately 12mm. To prevent ice buildup and track freezing, the doors include integrated heating cables and dual-shaft rolling systems for continuous operation.

What tools and preparation are needed for installation?

To prepare for installation, ensure the wall is level and free of obstructions. Essential tools include:

Measurement & Leveling: Tape measure, laser level, and plumb bob to ensure vertical alignment.

Installation Tools: Impact drills, hand drills, screwdrivers, welding machines (if required), and a sturdy ladder or scissor lift for header mounting.

Related services provided by Jiya Intelligent

No posts found!

Latest Blog Posts about RV Power Pedestals

Learn more about CNC stainless steel processes of machining, purposes of applications and all the most current developments. Don’t miss out on reading our professional blog redirection and come learn more!

Posts not found

Getting a quote for stainless steel cnc machining services

Would you like to invest in superior stainless products made precisely to last? If yes, kindly contact us to discuss the specifics of the project or ask for a custom quotation.

Frequently Asked Questions

How does a High Speed Insulated Door save energy in cold storage?

High Speed Insulated Doors reduce energy consumption by minimizing the time the door stays open and limiting cold air leakage. Their high-speed operation, insulated panels, and tight seals lower refrigeration load, helping facilities save on power costs and improve cold chain efficiency.

What temperature range can Cold Storage High Speed Doors operate in?

Cold Storage High Speed Doors are engineered to perform reliably in both refrigerated (0°C ~ 5°C) and freezer (-18°C to -30°C or lower) conditions. Many models include built-in anti-freeze features to ensure consistent operation in deep-freeze environments.

What industries use Cold Storage High Speed Doors?

These doors are widely used in food processing and storage, pharmaceutical cold rooms, logistics & cold chain warehouses, supermarket freezers, and biological sample storage facilities where precise temperature control and high throughput are required.

What maintenance is needed for Cold Storage High Speed Doors?

Routine maintenance includes checking the door motor, sensors, seals, and tracks to ensure optimal performance. Regular inspections and preventive service help maintain insulation efficiency, reduce downtime, and extend the door’s lifespan in cold environments.

What is the lifespan of a Cold Storage High Speed Door?

With proper installation and average traffic, a high-quality rapid door can last 7 to 10 years.