Dock Lveler

Top Dock Leveler Manufacturer and Supplier in China

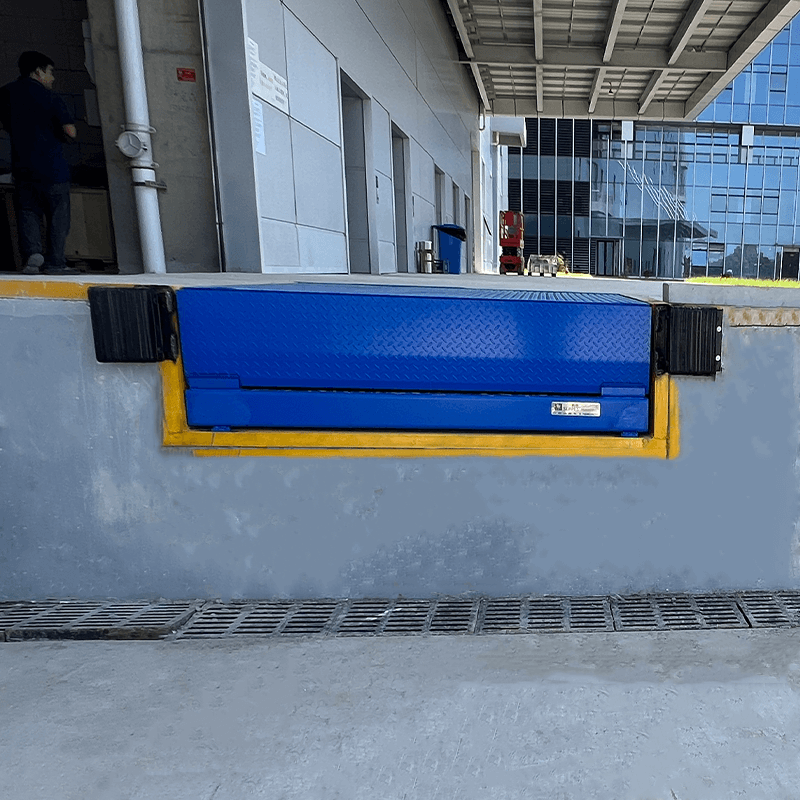

SEPPES stands as China's top dock leveler manufacturer and supplier by delivering innovative, cost-effective, and globally recognized solutions that prioritize quality, safety, and customer satisfaction.

Home » Dock Equipment » Dock Leveler

Durable and Reliable Dock Levelers for Efficient Loading & Unloading Operations

-

Efficient Operations: Advanced lifting mechanisms ensure smooth and precise alignment for seamless loading and unloading.

-

Robust Durability: Built with reinforced steel construction to handle heavy loads and withstand high-traffic industrial use.

-

Enhanced Safety: Equipped with fail-safe velocity fuses and maintenance struts to prioritize workforce safety.

-

Low Maintenance: Engineered for longevity, reducing downtime and ensuring consistent performance.

-

Productivity Boost: Designed to streamline operations and enhance efficiency in warehouses and distribution centers.

Key Features of Warehouse Dock Leveler

Durable and efficient power pedestals with customizable options, providing reliable energy solutions tailored to your needs.

Heavy-Duty Performance

Built with high-strength materials to handle substantial loads and constant use, ensuring long-term operational integrity.

Integrated Safety

Equipped with essential safety elements like velocity fuses to prevent sudden drops and maintenance struts to secure the unit for servicing.

Advanced Lifting Systems

Utilize powerful hydraulic or mechanical controls for precise, seamless alignment, creating a safe and stable path for forklifts.

Operational Efficiency

Drastically reduces loading and unloading times by creating a direct, smooth bridge, boosting overall productivity and throughput.

Heavy-Duty Hydraulic Dock Levelers for Efficient Loading

- Effortless Operation: Hydraulic systems provide smooth lifting, quick alignment, reducing strain, and speeding up loading and unloading processes.

- Extreme Durability: Reinforced steel construction ensures long-term performance, handling heavy loads and high-frequency industrial use efficiently.

- Enhanced Safety: Features velocity fuses and maintenance struts to prevent accidents and secure the dock leveler during servicing.

- Boosted Efficiency: Reduces loading times, minimizes product damage, and enhances operational throughput for improved productivity and profitability.

The Evolution of Hydraulic Dock Leveler Performance

- Precision Control: Advanced hydraulics and IoT integration ensure smooth transitions, synchronized equipment, and enhanced safety.

- Energy Efficiency: On-demand hydraulic systems minimize energy use, cutting costs and reducing environmental impact.

- Durability and Safety: Reinforced steel prevents warping, velocity fuses ensure safety, and self-cleaning hydraulics reduce maintenance.

- Future-Proof Operations: Modern hydraulic dock levelers improve speed, safety, and reliability, transforming loading docks into efficient hubs.

Loading Dock Leveler Detailed Technical Specifications

| Specification | Details |

|---|---|

| Dimensions | |

| Standard Size (W x L x H) | 2000mm x 2500mm x 600mm |

| Performance | |

| Adjustable Load Capacity | 6T / 8T / 10T / 12T options available |

| Lip Length | 400mm |

| Construction & Materials | |

| Platform Material | 8mm thick high-strength patterned steel plate |

| Standard Colors | Blue / Black / Gray (Custom colors available upon request) |

| Power & Control | |

| Power Package | German brand |

| Motor Specifications | 380V, 50Hz, 0.75KW |

| Protection Class | IP54 (Protected against dust ingress and water spray) |

| Installation | |

| Recommended Environment | Factory / Warehouse loading bays |

Key Features to Consider When Choosing a Hydraulic Dock Leveler

Load Capacity

- Details: Ensure the dock leveler can handle the maximum weight of your heaviest loads, including forklifts and cargo.

- Data: Common load capacities range from 25,000 lbs to 80,000 lbs, depending on industrial requirements.

Safety Features

- Velocity Fuses: Automatically lock the platform during sudden free-fall, ensuring worker and equipment safety if a truck departs prematurely.

- Maintenance Struts: Securely hold the dock leveler during servicing, preventing accidental collapses and ensuring safety for maintenance personnel.

- Safety Interlocks: Synchronize with vehicle restraints and traffic lights, preventing premature truck movement and reducing accident risks.

Durability and Construction

- Details: Choose levelers made from high-tensile steel with reinforced beams to withstand heavy traffic and long-term use.

- Data: High-quality materials reduce wear and tear, ensuring a lifespan of 10+ years with proper maintenance.

Discover Reliable Hydraulic Dock Leveler Solutions for Your Warehouse or Facility

Find reliable power solutions for your home or business, including backup generators and energy-efficient systems to save costs and keep operations running smoothly.

Customizable Design: SEPPES offers tailored solutions to fit specific facility needs, including adjustable sizes, colors, and load capacities (6T to 15T).

Advanced Safety Features: Equipped with velocity fuses, anti-slip surfaces, and safety solenoid valves to prevent accidents and ensure secure operations.

Durability and Efficiency: Built with high-strength steel and advanced hydraulic systems, these levelers ensure long-term reliability and smooth operation.

Global Trust: SEPPES serves over 5,600 companies worldwide, including Fortune 500 firms, with CE-certified products and excellent after-sales support.

Effortless Manual Operation: Features a spring counterbalance system and pull-chain mechanism for smooth, energy-efficient operation without hydraulics.

Durable Construction: Built with high-tensile steel and reinforced design to handle heavy forklift loads and prevent warping.

Safety Features: Includes safety legs, struts, and a safe working range to ensure secure and reliable operations.

Low Maintenance: Simple design reduces upkeep to basic lubrication and spring adjustments, offering a cost-effective solution.

Space-Saving Design: Mounts directly to the dock face, eliminating the need for pits and saving space in tight loading zones.

Cost-Effective Solution: Offers professional-level functionality at a fraction of the cost, ideal for facilities with standard truck heights.

Enhanced Safety: Features slip-resistant surfaces, ergonomic operation, and secure positioning to prevent accidents and injuries.

Durable and Low Maintenance: Built with heavy-duty steel for long-term use and requires minimal upkeep, ensuring reliable performance.

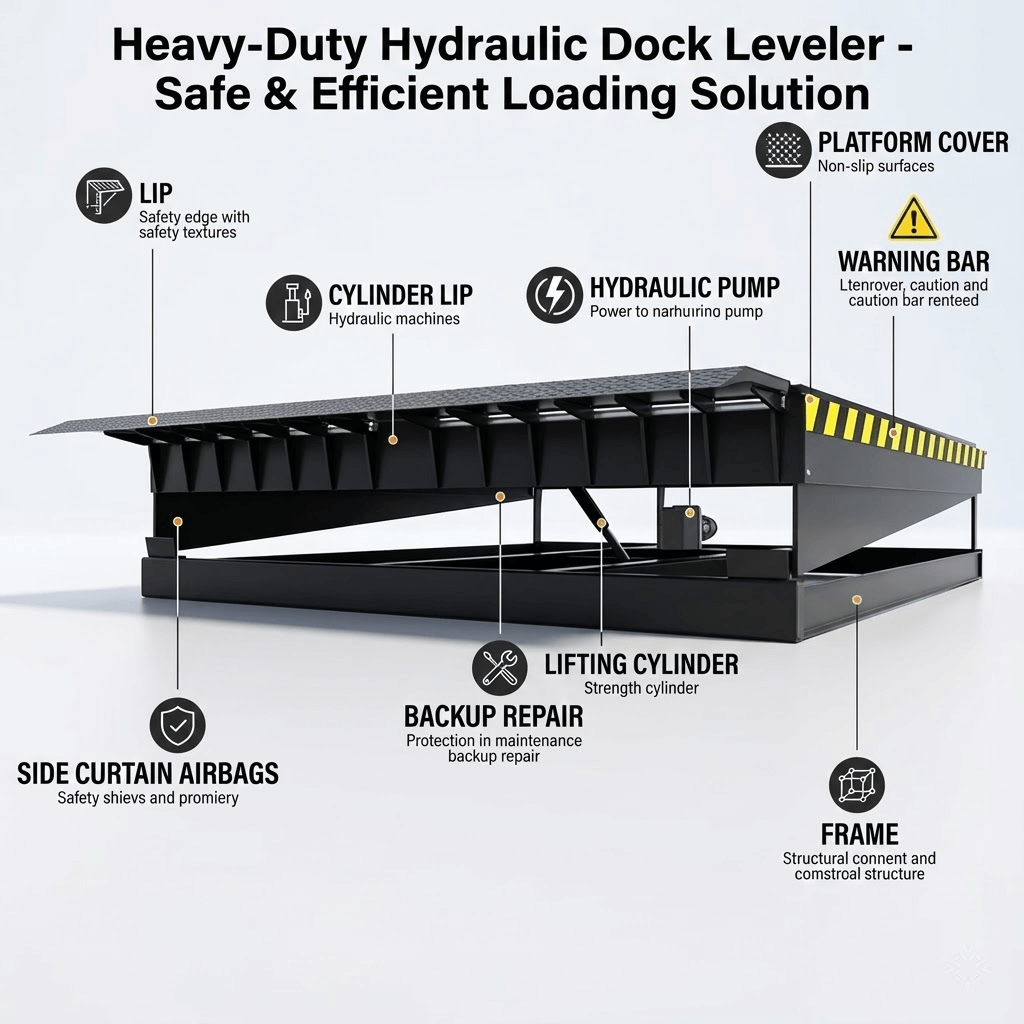

Key Components of a Dock Leveler That Affect Performance

Innovative Lip Details

The double 5° arch bridge lip ensures a stable and secure connection with truck beds, minimizing impacts and protecting equipment and cargo.

Protective Side Seals

Durable rubber strips close gaps, preventing dust, debris, and energy loss, while maintaining a clean and controlled warehouse environment.

.jpg)

Optional Dual Hydraulic Pump

Adds a second pump for smoother, more reliable lifting, ideal for high-traffic environments and heavy loads.

Reinforced Motherboard Stiffener

Heavy-duty steel beams reinforce the platform, ensuring stability, preventing warping, and extending the leveler’s lifespan.

Comparison of Different types of dock Leveler

| Type | Operation | Load | Maintenance | Cost | Power | Use Case |

|---|---|---|---|---|---|---|

| Mechanical | Manual | Medium | Moderate | Low | None | Basic Ops |

| Hydraulic | Automatic | Heavy | Low | High | Required | High Traffic |

| Air-Powered | Semi-Auto | Medium | Moderate | Moderate | Required | Temp Control |

| Vertical | Auto | Heavy | Low | High | Required | Hygiene |

| Edge-of-Dock | Manual/Auto | Light | Low | Low | Optional | Small Spaces |

| Telescoping Lip | Auto | Heavy | Moderate | High | Required | Versatile |

| Recessed | Manual/Auto | Heavy | Moderate | High | Optional | Seamless Fit |

| Specialty | Custom | Varies | Varies | High | Optional | Unique Needs |

Hydraulic Dock Leveler Specifications for Industrial Loading Docks

| pecification | Details |

|---|---|

| Operation | Fully automatic |

| Load Capacity | Medium to heavy (6T-12T) |

| Power Source | Hydraulic system (380V) |

| Material | High-tensile steel |

| Platform Thickness | 8mm patterned steel plate |

| Lip Length | 400mm |

| Protection Class | IP54 |

| Color Options | Blue, Black, Gray (customizable) |

| Installation | Factory/Warehouse |

| Maintenance | Low |

| Energy Efficiency | Moderate |

Common Applications for Dock Leveler

Why Choose Our Custom Loading Dock Leveler Solutions

SEPPES offers custom-designed dock levelers to meet unique facility needs, optimizing efficiency with precise sizing, load capacity, and industry-specific features. Advanced safety technologies and robust construction ensure reliability and help prevent accidents. Trusted globally, SEPPES holds certifications like EU CE and SGS, and is recognized for patented innovations that enhance performance. With over 5,600 satisfied clients in 75+ countries, SEPPES delivers tailored solutions, expert consultation, and full after-sales support. Choose SEPPES for efficient, safe, and long-lasting dock leveler systems backed by proven expertise and a commitment to quality.

SEPPES Proven Expertise and Project Experience Across Diverse Industries

- Hygienic stainless steel dock levelers for food processing plants

- GMP-compliant hydraulic dock levelers for pharmaceutical loading bays

- Thermal-insulated telescopic dock levelers for cold storage logistics

- Wash-down rated dock levelers for meat and dairy processing facilities

- Airtight loading dock levelers for temperature-sensitive medicine warehouses

- Anti-corrosion galvanized dock levelers for seafood distribution centers

- High-capacity reinforced dock levelers for automotive assembly lines

- Heavy-duty impact-resistant dock levelers for steel and metal industries

- Extra-long telescopic lip dock levelers for aircraft component logistics

- High-cycle automatic dock levelers for heavy machinery manufacturing

- Super-load bearing pit-mounted dock levelers for construction equipment hubs

- Custom-sized hydraulic dock levelers for oversized vehicle loading

- Anti-static surface dock levelers for precision electronics factories

- Explosion-proof hydraulic dock levelers for chemical production sites

- Dust-sealed loading dock levelers for semiconductor cleanroom logistics

- Spark-resistant dock levelers for hazardous material handling areas

- Precision-leveled dock platforms for fragile glass and optic manufacturing

- Space-saving vertical dock levelers for urban retail distribution poin

- Low-profile mechanical dock levelers for small-scale parcel hubs

- Smart-control integrated dock levelers for automated smart warehouses

- Energy-efficient edge-of-dock levelers for green building logistics

- All-weather outdoor dock levelers for port and maritime terminals

- Safety-first interlocking dock levelers for high-traffic logistics parks

- Aesthetic recessed dock levelers for high-end commercial showrooms

What Our Client Says

Build your project with confidence knowing that customers across industries trust baetro

Expert Guides to Custom Dock Leveler Solutions

How Does a Hydraulic Dock Leveler Work?

A hydraulic dock leveler uses a hydraulic pump and cylinder to raise and lower the platform smoothly during loading.

What Is the Standard Load Capacity of a Hydraulic Dock Leveler?

Typical load capacities range from 6 to 15 tons, depending on design and application.

What Are the Key Components of a Hydraulic Dock Leveler?

Main components include the hydraulic power unit, cylinders, platform, lip, and control system.

What Dock Pit Size Is Required for a Hydraulic Dock Leveler?

Dock pit dimensions vary by model and must match the platform size and lip extension.

How Fast Does a Hydraulic Dock Leveler Operate?

Hydraulic dock levelers typically complete a full operating cycle within a few seconds.

What Safety Features Are Included in Hydraulic Dock Levelers?

Common features include safety legs, overload protection, emergency stop, and anti-fall systems.

Can a Hydraulic Dock Leveler Handle Different Truck Heights?

Yes, it is designed to accommodate a wide range of truck bed heights automatically.

What Maintenance Does a Hydraulic Dock Leveler Require?

Routine inspection of hydraulic oil, seals, and moving parts ensures stable performance.

Related services provided by SEPPES

No posts found!

Latest Blog Posts about Dock Levelers

Learn more about hydraulic loading dock systems, heavy-duty structural engineering, and the most current warehouse logistics developments. Don’t miss out on reading our professional blog redirection and come learn more!

Posts not found

Getting a quote for SEPPES Hydraulic dock leveler services

Would you like to invest in superior dock levelers made precisely to last? If yes, kindly contact us to discuss the specifics of the project or ask for a custom quotation.

Frequently Asked Questions

What is the primary purpose of a dock leveler?

A dock leveler is a piece of equipment that creates a fixed bridge between your loading dock and the bed of a transport truck. Its main purpose is to compensate for the height difference between the two surfaces. This allows forklifts and other material handling equipment to move in and out of the truck smoothly and safely, which speeds up loading and unloading operations and reduces the risk of accidents or product damage.

What are the main types of dock levelers?

There are three primary types of dock levelers, each suited for different operational needs:

- Mechanical: These are manually operated using a pull-chain and are a cost-effective, reliable option for facilities with lower traffic volume.

- Hydraulic: Operated with the push of a button, these use hydraulic cylinders for smooth, powered control. They are ideal for high-traffic, heavy-load environments due to their ease of use and durability.

- Air-Powered: These use an inflatable airbag to raise and lower the platform. They offer a clean, low-maintenance alternative to hydraulics and are suitable for a wide range of applications.

How often does a dock leveler require maintenance?

Regular maintenance is crucial for safety and longevity. It is recommended to have your dock levelers professionally inspected and serviced at least once or twice a year, depending on their usage frequency. Daily visual checks by your staff can also help identify potential issues like debris in the pit or visible damage. Consistent maintenance helps prevent unexpected breakdowns and ensures the equipment operates safely.

What are the most important safety features to look for in a dock leveler?

Modern dock levelers come with several essential safety features. Key ones include:

Velocity Fuse: A critical safety stop that prevents the platform from free-falling if a truck unexpectedly pulls away.

Full-Range Toe Guards: These shields run the full length of the leveler’s sides to prevent foot injuries when the platform is raised.

Maintenance Strut: A sturdy support that locks the deck in a raised position, allowing technicians to safely perform maintenance underneath.

Can a dock leveler be customized for a specific facility?

Yes, absolutely. Dock levelers can be custom-manufactured to fit your facility’s unique requirements. Customization options include specific dimensions to fit non-standard pits, higher load capacities (from 25,000 lbs to over 100,000 lbs), and specialized materials like galvanized steel for corrosive or cold storage environments. You can also customize features like the lip length and control systems to perfectly match your operational workflow.