Sectional Door

China's Leading Manufacturer and Supplier of Industrial Sectional Doors

As China’s leading industrial door manufacturer, SEPPES offers reliable and high-performance sectional overhead door solutions for warehouses, logistics centers, and manufacturing plants. Our dedicated engineering team provides both customized and standard products designed to withstand the most demanding environments. Discover the unmatched durability and security of SEPPES sectional doors and contact us today so you don't miss out on our expert technical support and exceptional service!

Home » Dock Equipment » sectional door

Durable, Insulated Industrial Sectional Door for Your Facility Needs

Superior Thermal Performance & Space-Saving Design

Excellent Thermal Insulation for Energy Efficiency Constructed with high-density polyurethane sandwich panels to maintain stable indoor temperatures and reduce energy costs.

Space-Saving Track Designs for Maximum Clearance Offers various lift configurations—including standard, high, and vertical lifts—to optimize your facility’s overhead space.

Robust Steel Construction for Enhanced Security and Durability

Customizable Vision Panels and Colors to Suit Your Branding

Advanced Safety Protection with Anti-Fall and Sensor Systems

Key Features of Our Sectional Doors

Make Your Factory Look Cleaner and Your Entrance Gate Smarter.

Thermal Insulation

The door panel has a minimum thickness of 40 millimeters and is filled with polyurethane foam insulation, providing excellent protection to maintain a stable internal temperature.

Wind Resistance

Each door panel is connected using reinforced hinges, and the tracks are made of galvanized material at least 2 mm thick to secure the door panels.

Sealing Structure

The top, sides, and bottom are all fitted with EPDM sealing strips. The door panels are connected with sealing rubber strips to prevent dust and dirt ingress.

Security System

Four major safety devices: bottom airbag safety device, steel wire rope anti-fall device, torsion spring anti-break device, and end buffer device.

Industrial Sectional Doors (High Insulation)

- Superior Thermal Performance: Features double-skinned steel panels with high-density polyurethane cores for maximum energy efficiency and temperature control.

- Advanced Weather Sealing: Equipped with perimeter EPDM seals to prevent wind, dust, and moisture infiltration, maintaining a clean indoor environment.

- Smooth & Quiet Operation: Precision-engineered tracking systems allow for vertical or high-lift opening, significantly reducing mechanical noise compared to rolling doors.

- High Aesthetic Customization: Available in various textures, RAL colors, and vision windows to enhance the building's facade and workplace visibility.

Steel Rolling Shutter Doors (Space-Saving)

- Compact Headroom Design: The curtain rolls into a small overhead drum, maximizing usable ceiling space for lighting and overhead cranes.

- Robust Security Barrier: Constructed with interlocking galvanized steel slats that provide high resistance against unauthorized entry and impact.

- Versatile Installation: Flexible mounting options allow it to fit almost any architectural opening without requiring extensive overhead tracking systems.

- Fire Safety Integration: Can be specially configured with fire-rated slats and automated gravity-drop systems for critical fire protection zones.

Sectional Door Detailed Technical Specifications

| Product Name | Standard Sectional Door | Insulated High-Lift Door | Full View Aluminum Door | Vertical Lift Heavy Door |

|---|---|---|---|---|

| Product Features | Thermal Insulation: Good Wind Resistance: High Security: Excellent Sealing: Standard | Thermal Insulation: Excellent Wind Resistance: High Security: Excellent Sealing: Enhanced | Thermal Insulation: Standard Wind Resistance: Good Visibility: 100% Full View Aesthetics: Excellent | Thermal Insulation: Good Wind Resistance: Ultra-High Durability: Heavy Duty Size: Custom Large |

| Max Size | W8000 * H8000mm | W6000 * H7000mm | W5500 * H5000mm | W12000 * H10000mm |

| Panel Material | 40mm/50mm Double-sided Steel with PU Foam | 50mm/75mm High-density PU Sandwich Panel | Aluminum Alloy Frame + Polycarbonate/Tempered Glass | 50mm/75mm Reinforced Steel Panel |

| Panel Thickness | 40mm / 0.5mm Steel Sheet | 50mm / 0.6mm Steel Sheet | 2.0mm Aluminum Profile | 50mm / 0.8mm Steel Sheet |

| Panel Color | White / Grey / Blue / Red / Silver | (Same as Standard) | Silver / Black / Wood Grain / RAL Colors | (Same as Standard) |

| Track System | Standard Lift / High Lift | Vertical Lift / Roof Follow Lift | Standard Lift / High Lift | Vertical Lift |

| Track Material | 2.0mm Galvanized Steel | 2.0mm/3.0mm Galvanized Steel | 2.0mm Galvanized Steel | 3.0mm Heavy Duty C-Channel Steel |

| Wind Load Class | Class 3-4 (≤ 700Pa) | Class 4 (≤ 900Pa) | Class 2-3 (≤ 500Pa) | Class 5-6 (≤ 1100Pa) |

| Motor Power | 0.37Kw / 0.55Kw / 0.75Kw | 0.75Kw / 1.5Kw | 0.37Kw / 0.55Kw | 1.5Kw / 2.2Kw |

| Opening Speed | 0.15 - 0.25m/s | 0.15 - 0.25m/s | 0.15 - 0.20m/s | 0.10 - 0.20m/s |

| Operation Way | Automatic / Remote / Chain Hoist | Automatic / Chain Hoist | Automatic / Remote | Automatic / Chain Hoist |

| Balance System | Torsion Spring (25,000 cycles) | Torsion Spring (50,000 cycles) | Torsion Spring (25,000 cycles) | Heavy Duty Counterweight / Torsion Spring |

| Safety Devices | Airbag / Spring-break Protection / Cable-break Protection | (Same as Standard) + Light Curtain | (Same as Standard) + Photocell | (Same as Standard) + Double Cable Support |

| Vision Window | Optional (600*300mm / Oval) | Optional (Double-layer Acrylic) | N/A (Full Panel Visibility) | Optional (Reinforced Glass) |

| Sealing Structure | EPDM Top/Bottom/Side Seals | Dual-density EPDM Arctic Seal | EPDM Rubber Seal | Industrial Heavy Duty Brush & Rubber Seal |

| Working Temp. | -30℃ ~ +70℃ | -40℃ ~ +70℃ | -20℃ ~ +60℃ | -30℃ ~ +70℃ |

| Track Dimensions | 2-inch (50mm) / 3-inch (76mm) | 3-inch (76mm) | 2-inch (50mm) | 3-inch (76mm) |

Key Features to Consider When Choosing a Sectional door

Durable and robust, providing all-weather protection

Durable and robust sectional overhead doors, typically constructed from double-layered high-strength steel panels filled with high-density polyurethane foam, provide reliable access control in demanding outdoor and industrial environments. Designed to withstand strong winds, extreme temperature fluctuations, and moisture corrosion, these doors have become the preferred standard for modern logistics centers, large manufacturing plants, and warehousing facilities. Their sturdy structural design and excellent insulation properties translate into years of trouble-free operation, giving managers confidence in their long-term performance and safety.

Safety and Protection Systems

- Torsion spring break devices are needed to be installed with any industrial sectional door in a logistics or manufacturing center owing to strict mechanical safety code compliance.

- Closing hazards are common in busy docks, so safety technology such as bottom safety airbags (safety edges) are used widely to ensure protection while vehicles and personnel are passing through.

- Installing wire rope break protection protects the users and heavy door panels from getting damaged and minimizes potential loss due to suspension failure, preserving service reliability for future operations.

Customization Options for Specific Needs

Because no two building openings are identical, manufacturers offer a range of customizable configurations—allowing facility managers to specify panel thickness, track lift types, and window arrangements that best suit each application. Options such as pedestrian pass doors (wicket doors), vision panels, and automated radar sensors streamline workflow efficiency while maintaining indoor temperature stability. This adaptability means managing traffic at a busy logistics dock or sealing a temperature-controlled warehouse, the sectional door can meet operational goals without compromise.

Choose The Optimal Installation Method For Your Sectional Doors

SEPPES provides flexible track configurations to maximize your facility's overhead space and operational efficiency.

Compact horizontal tracking for limited headroom

Cost-effective solution for general warehousing

Reliable and versatile for commercial garages

Easy maintenance with a simple track design

Maximizes wall space for high-racking systems

Safely positions tracks away from forklift paths

Customizable vertical travel before turning

Improved clearance for lighting and ventilation

Zero overhead obstruction for maximum volume

Complete vertical tracking against the facility wall

Optimal clearance for high-ceiling industrial plants

Engineered for extra-large industrial openings

Special Configurations and Applications of Sectional Doors

Integrated Wicket Door

Convenient Personnel Access Designed for high-traffic facilities, our integrated wicket doors (pass doors) allow for easy personnel entry and exit without needing to open the entire sectional door. This feature significantly reduces energy loss, maintains indoor temperature, and extends the lifespan of the main drive system by reducing unnecessary cycles.

Reinforced Wind-Resistant Panels

Maximum Structural Integrity For ultra-wide openings or areas prone to extreme weather, we offer panels with external "back rib" reinforcements. These thickened steel stiffeners provide superior structural rigidity, allowing the door to withstand high wind loads while preventing panel deflection or bowing over long-term use.

Explosion-Proof Drive System

Safety for Hazardous Environments Engineered specifically for industries such as chemical processing, oil & gas, or pharmaceutical labs. This system utilizes ATEX/IECEx certified motors and spark-free control boxes. It ensures stable, automated operation while meeting the highest safety standards for volatile or combustible atmospheres.

Bespoke Finishes & Textures

Tailored Architectural Aesthetics Beyond standard industrial gray, we provide a full spectrum of RAL color customization and surface textures. Choose from woodgrain, stucco, or micro-ribbed finishes with high-performance powder coating to match your corporate branding or the specific architectural requirements of your facility.

Key Components of Industrial Sectional Overhead Doors

High-Insulation Panels

Constructed with double-sided galvanized steel skins and high-density CFC-free Polyurethane (PU) foam. Featuring a thickness of 40mm/50mm, these panels provide exceptional thermal insulation, wind resistance, and structural integrity.

Heavy-Duty Track System

Built from 2.0mm+ hot-dipped galvanized steel. The optimized track geometry combined with high-quality nylon rollers ensures silent, smooth operation and long-term durability even in high-frequency usage environments.

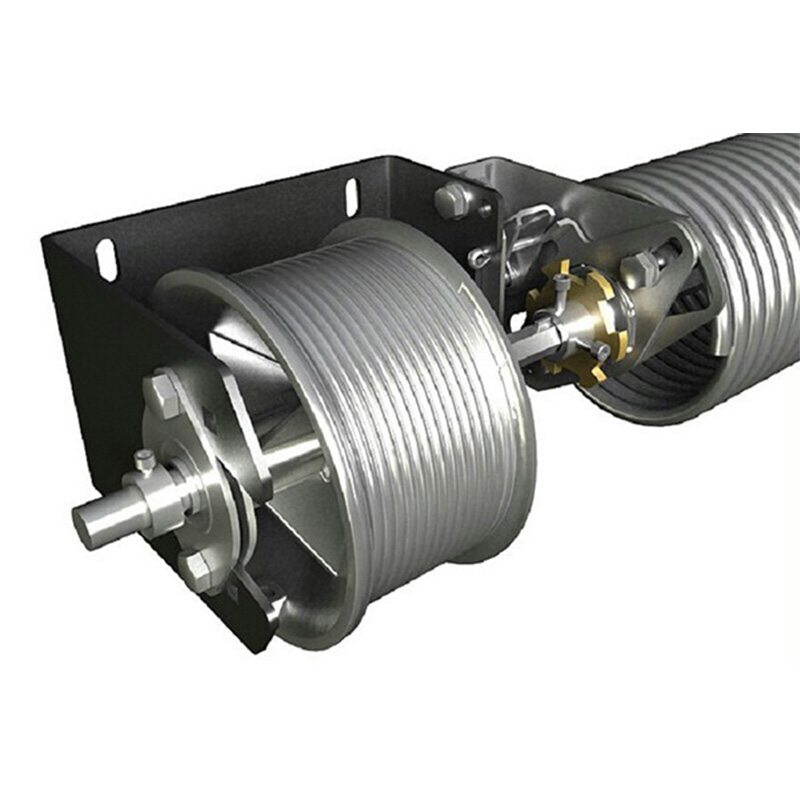

Precision Balance System

Our engineers use specialized software to calculate the exact torsion spring requirements for every door. This ensures a perfect counterbalance, making even large doors easy to operate manually and reducing the load on the motor.

Intelligent Drive System

Features advanced soft-start and soft-stop technology to minimize mechanical wear and extend the door's lifespan. The intelligent control box ensures stable performance even in high-frequency environments

Common Applications for Industrial sectional doors

Why Choose Our Sectional Overhead Doors?

1. Superior Cost-Effectiveness SEPPES sectional doors offer a 30-50% price advantage over Western brands while maintaining high performance, ensuring significant savings for large-scale industrial projects.

2. Efficient Lead Times Our optimized production line guarantees rapid delivery within 30-45 days for bulk orders, effectively reducing project wait times and installation delays.

3. Flexible Customization We provide bespoke solutions for various track configurations (Standard, High, or Vertical Lift) and panel materials to fit unique architectural and operational requirements.

4. Certified Quality & Insulation Compliant with CE and ISO standards, our doors feature high-density thermal insulation and robust hardware for exceptional durability, energy efficiency, and safety.

5. Responsive Global Support We offer comprehensive warranties and expert technical guidance, including quick spare parts supply and remote troubleshooting to ensure long-term, reliable operation.

Sectional Door Expertise And Project Experience Across Diverse Industries

- Thermal Insulated Sectional Doors For Cold Storage Logistics

- High-Lift Sectional Doors For Large-Scale Distribution Centers

- Heavy-Duty Industrial Doors For Manufacturing & Assembly Plants

- Wind-Resistant Sectional Doors For Coastal Loading Bays

- Quick-Response Overhead Doors For Fire Stations & Emergency Services

- Durable Steel Sectional Doors For General Industrial Warehousing

- Extra-Wide Sectional Doors For Aircraft Hangars & Maintenance

- Vertical Lifting Doors For High-Ceiling Production Workshops

- Automated Sectional Doors For Smart Logistics & Sorting Hubs

- Anti-Corrosive Sectional Doors For Chemical & Fertilizer Plants

- Security Sectional Doors For Underground Commercial Parking

- Space-Saving Vertical Lift Doors For Low-Headroom Warehouses

- Pedestrian-Integrated Doors For Staff Access Without Full Opening

- Full-Vision Aluminum Doors For Automotive Showrooms & Dealerships

- Weather-Sealed Overhead Doors For Extreme Climate Environments

- Sandwich Panel Sectional Doors For Precision Temperature Control

- Aesthetic Glazed Sectional Doors For Modern Commercial Facades

- Impact-Resistant Sectional Doors For High-Traffic Forklift Zones

- Energy-Efficient Sectional Doors For Sustainable Green Buildings

- Sound-Insulating Sectional Doors For Noise-Sensitive Workshops

- Custom-Color Sectional Doors For Brand-Specific Corporate Identity

- Fire-Rated Sectional Doors For Hazardous Material Storage Areas

- High-Security Sectional Doors For Military & Government Logistics Bases

- Vision-Panel Sectional Doors For Natural Lighting In Work Areas

What Our Client Says

Build your project with confidence knowing that customers across industries trust SEPPES

Expert Guides To Custom Industrial Sectional Doors

Can industrial sectional doors be customized for extra-large openings?

Yes. We provide custom solutions for openings up to 12m wide. Reinforced wind-resistant ribs and heavy-duty track systems ensure structural stability for oversized doors.

What factors influence the cost of a sectional door?

Hourly rates or unit prices are affected by panel thickness, lift configuration (Standard, High, or Vertical), motor specifications, and custom features like vision windows.

How do sectional doors improve facility energy efficiency?

Our doors use high-density PU foam panels and EPDM perimeter seals. This design minimizes heat transfer, significantly reducing energy costs for climate-controlled warehouses.

What are the different track lift options available?

We offer Standard, High, and Vertical lift configurations. These options allow you to maximize your facility’s headspace and avoid interference with overhead cranes or pipes.

What safety systems are included as standard?

Every door includes spring-break protection, cable-failure safety devices, and a bottom safety edge (airbag) to reverse the door immediately if an obstruction is detected.

How long is the lifespan of the torsion spring system?

Standard springs are rated for 25,000 cycles, while our heavy-duty options can reach 100,000 cycles, ensuring long-term reliability for high-frequency loading docks.

Can these doors withstand high wind load conditions?

Yes. Our sectional doors are engineered to reach Wind Class 3 or 4. They are ideal for coastal regions or industrial parks prone to high wind pressure.

What is the main advantage of sectional doors over rolling doors?

Sectional doors offer superior thermal insulation, higher security, and quieter operation. They also allow for large vision panels to improve natural lighting and safety.

Related services provided by SEPPES Door

No posts found!

Latest Blog Posts about Industrial Sectional Doors

Learn more about industrial sectional doors , purposes of applications and all the most current developments. Don’t miss out on reading our professional blog redirection and come learn more!

Posts not found

Getting a quote for stainless steel cnc machining services

Would you like to invest in superior stainless products made precisely to last? If yes, kindly contact us to discuss the specifics of the project or ask for a custom quotation.

Frequently Asked Questions

Q: What type of track lift fits my building if I have limited headroom?

A: We offer customizable track configurations to suit different building structures. Besides the Standard Lift, we provide High Lift (for higher ceilings) and Vertical Lift (for high-bay warehouses) to maximize your vertical space utilization. Just send us your opening dimensions and ceiling height, and we will design the optimal solution.

Q: How does the sectional door perform in extreme weather conditions?

A: Our doors are constructed with double-layer galvanized steel sheets filled with high-density polyurethane foam. This “sandwich” design, combined with all-around EPDM sealing strips, provides excellent thermal insulation and wind resistance, effectively keeping indoor temperatures stable and reducing energy costs.

Q: What safety features are included to prevent accidents?

A: Safety is our top priority. Every SEPPES sectional door comes standard with a Torsion Spring Break Device and a Wire Rope Break Device to prevent the door from falling in case of suspension failure. Additionally, a Bottom Safety Airbag (Safety Edge) automatically rebounds the door if it encounters an obstacle while closing.

Q: Can I integrate a pass door for personnel without opening the main door?

A: Yes, we can install a Pedestrian Wicket Door within the main sectional door panels. This allows people to enter and exit quickly without operating the large door, which extends the motor’s lifespan and minimizes heat loss.

Q: How do I operate the door if there is a power outage?

A: Don’t worry. All our motorized sectional doors are equipped with a Manual Chain Hoist. In the event of a power failure or emergency, you can easily switch to manual mode and open or close the door using the hand chain.